A new look at an old age product in the building industry

Porcelain brick products

Alborz Ceramic is one of the most prestigious brands of luxury design in the production of glazed tiles and mosaics that was founded in 1973. Alborz Ceramic products are manufactured using European state of the art technology and the most modern machineries in accordance with European standards. Friction, freezing, acids and thermal shocks resistance are some of the most important benefits of these products. The products of this company are suitable for all indoor and outdoor areas and a large volume of these products are exported to Europe, Africa, CIS countries, Arab states, New Zealand, Australia and South American countries.

History

Iran a country which has been associated with ancient history and civilization in the arts and industry and has rich reserves of raw materials from the long time ago has been mentioned, as the appropriate bedding for the tile and ceramic industry, and it is possible to refer to the history of this ancient art to the inscribed insignia of Susa to the Achaemenes palace.

This industry was developed further in terms of quality and quantity after Islam. Iranian architects used tiles first in combination with bricks in the facades, and in the meantime, with the achievement of mosaic tile technology, adobe tile (seven colors) added to the use of this material.

Porcelain brick

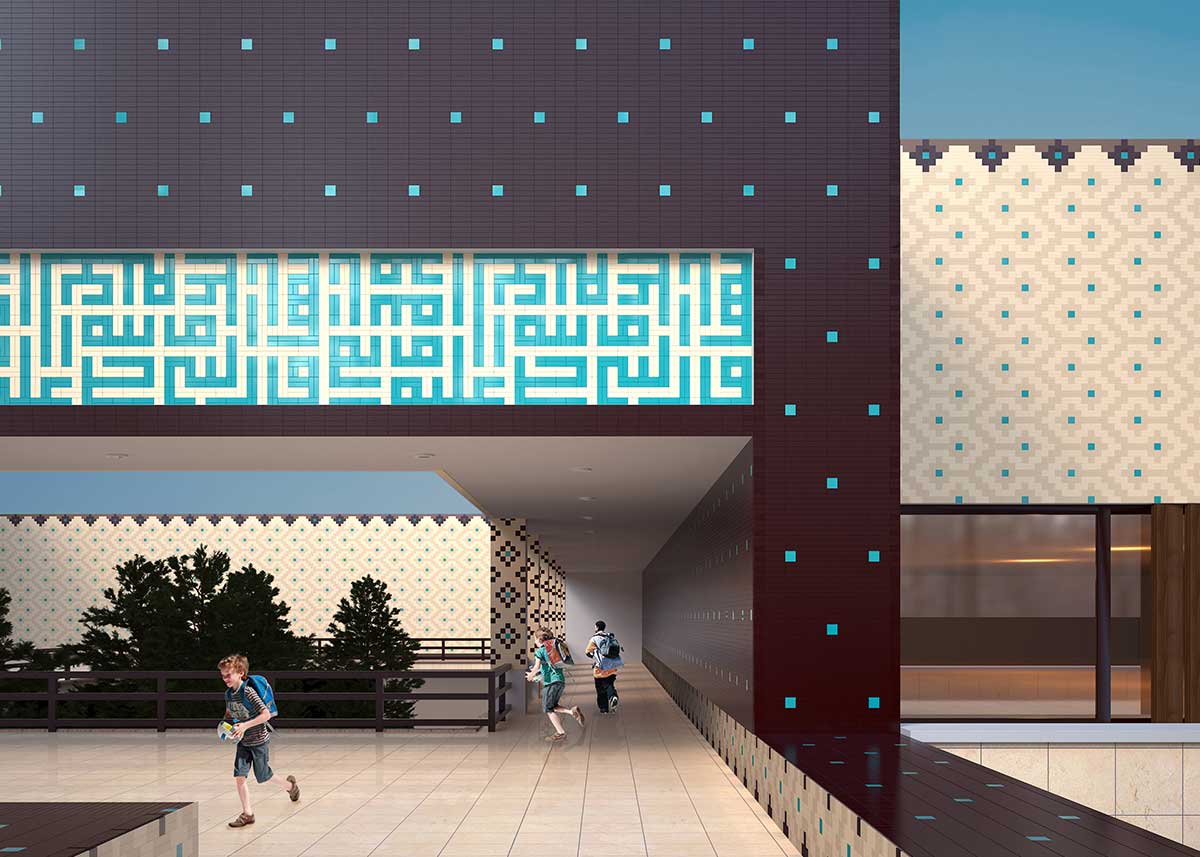

The Alborz Ceramic Company, based on its technical knowledge and artistic creativity, began a new effort to revive this original art in the ceramic industry. The company’s valuable experiences in producing high quality mosaic ceramic products and its export to many European, Asian and African countries have provided the ground for the production of a new product called “porcelain brick” in the building industry. Studies on this product began in 2013. In the following, with the formation of the “Allearbeed Atelier”, the technical and artistic characteristics of the product were determined and produced with various components in color and dimensions.

Quality Policy

The highest goal of the Alborz Complex is to provide customer satisfaction, therefore, we aim to rely on the knowledge, experience and commitment of our employees to achieve this, and paying precise attention to do the right thing from the beginning, to continuously improve our activities in all aspects. Considering that supplying the needs of customers and beneficiaries is the cornerstone of Alborz Ceramic Company’s activities in order to properly manage the quality in all processes, the company bases its quality management system on the basis of the international standard of quality management system ISO9001: 2008 and its effectiveness Is constantly evaluated.

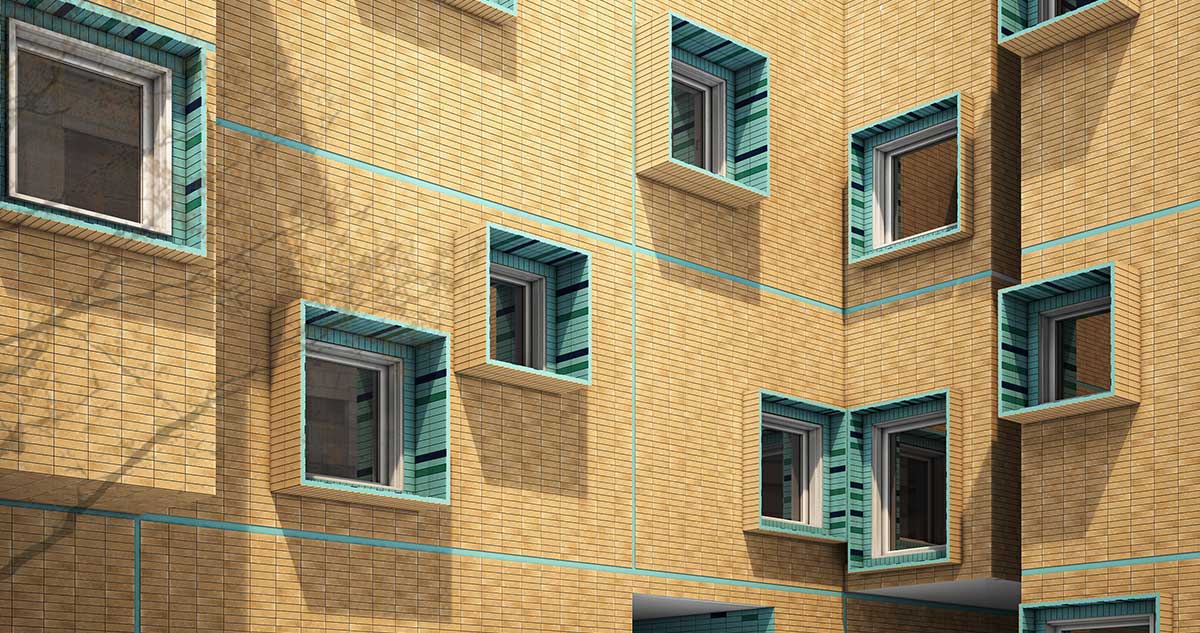

Porcelain brick products have been designed and manufactured with the aim of reviving the original art of bricklaying, which has long been present in Iranian architecture. These products have basic features such as color variation, fire retardant coatings, thermal shock, low moisture expansion, zero water absorption and …

All products are taken from original Iranian art. Unique collections inspired and designed by the mosque of Isfahan, Iranian old houses and the main colors of Iranian buildings. It is hoped that with the ever-increasing development of proposed designs, while securing consumer demands, we will take an effective step towards linking with cultural assets in the architecture of this realm.

Characteristics of porcelain brick

Porcelain brick products using European state of the art technology

Physical features are the quality assurance of the goods. Tips that guarantee the quality of the product during its performance and its durability over the years. Porcelain brick products with features such as good adhesion, constant and stable color, zero water absorption, very low moisture expansion, low linear thermal expansion, thermal shock resistance, resistant to most of chemical substances and very low stainability, provides you with a great lifetime product to ensure your peace of mind…

Undoubtedly, one of the reasons for choosing building materials is its structural and constructive features. In addition to assessing the quality of porcelain brickwork, the Alborz Architectural atelier has carried out major studies on the methods of implementation, and has introduced specific guidelines for ease of installation and optimization of structures. Some structural features of porcelain products include: reduction of thickness and weight of view Layer, structural weight reduction, reduce installation and run time, reduce the risk of debris in natural disasters, reduce the cost of implementation and fire resistance…

Obviously, each designer tends to create a work that includes aesthetic attributes, considering the elements of aesthetics as an artwork, has long been seen in the works of the predecessors. Hence, the Alborz Architectural Studio has been working to create a product proportional to the arts and craftsmanship of architects and construction specialists, a product that incorporates the following artistic features: color diversity, the ability to create the traditional and modern role of tones, the ability to use open spaces and landscaping, the possibility of work at all levels of the facade, covering surfaces with varied geometries, matte glaze and non-reflection of light…

Methods of implementation

The durability of the buildings made with each of the building elements along with the quality and variety of the product, has a profound dependence on the way of implementation. The way that you use each product and choose each product in accordance with the climatic and geographic conditions, as well as the general conditions of the structure, such as infrastructure, area of implementation, angles of surfaces, etc. and choosing implementation method impacts on the final quality of the project which will lead directly to the employer’s satisfaction. The porcelain brick, in order to guide the customer to achieve the best possible quality, introduces different ways to be with the beloved compatriots until the last minute.